JYP Series Fresh Water Generator

Category:

JYP Series Fresh Water Generator

Keywords:

JYP Series Fresh Water Generator

The water maker uses a seawater-driven gas-water mixing ejector to create a vacuum, allowing the replenishing seawater to evaporate at low temperatures (vacuum degree of approximately 94%, seawater starts to evaporate at 38°C).

Phone:

Email:

Product Details

Product Details

The water maker uses a seawater-driven air-water mixing ejector to draw a vacuum, allowing the feed seawater to evaporate at low temperature (vacuum degree about 94%, seawater evaporation starts at 38°C).

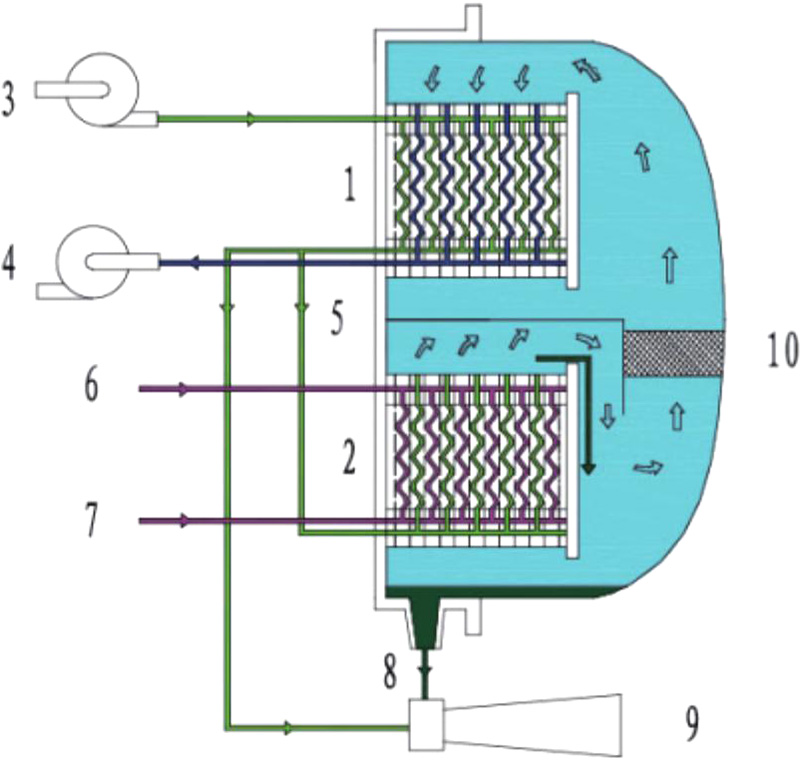

Working Principle

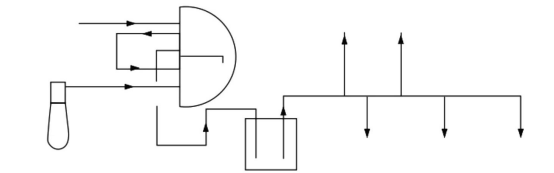

The water maker uses a seawater-driven air-water mixing ejector to draw a vacuum, allowing the feed seawater to evaporate at low temperature (vacuum degree about 94%, seawater evaporation starts at 38°C).

In the evaporator section, after the seawater evaporates, the separated brine is collected at the bottom of the separation chamber and then extracted and discharged overboard. After the separated steam is filtered to remove seawater droplets, it enters the condenser, where it is condensed into freshwater after heat exchange with the seawater in the adjacent flow channel. The condensed freshwater is extracted by the freshwater pump.

After the freshwater is tested by the salinometer, the qualified freshwater is sent to the freshwater tank, and the unqualified freshwater is discharged.

| 1 Condenser |

Dimensions

Model | Length/L mm | Length/L mm | Height/H mm | Net Weight/W kg |

JYP-16-40-3T | 850 | 750 | 1150 | 220 |

JYP-16-40-5T | 900 | 790 | 1200 | 260 |

JYP-16-40-7T | 900 | 830 | 1200 | 300 |

Main Components of JYP Series Water Makers

1. Evaporator (Titanium Plate)

The evaporator consists of a group of plate heat exchangers enclosed in the separation chamber.

2. Condenser (Titanium Plate)

Like the evaporator, the condenser also consists of a group of plate heat exchangers enclosed in the separation chamber.

3. Separation Chamber (Cast Brass, Stainless Steel)

The separation chamber separates the feed seawater into brine and water vapor.

4. Brine/Air Mixing Ejector (Cast Brass)

The ejector extracts the brine and uncondensed gases from the separation chamber.

5. Ejector Pump (Seawater Pump)

The seawater pump is usually configured by the manufacturer and is a single-stage vertical centrifugal pump. This pump provides cooling seawater for the condenser, driving seawater for the mixing ejector, and feed seawater for the evaporator.

6. Condenser Pump (Freshwater Pump)

The freshwater pump is a single-stage centrifugal pump. The freshwater pump extracts the produced freshwater from the condenser and sends it to the freshwater tank.

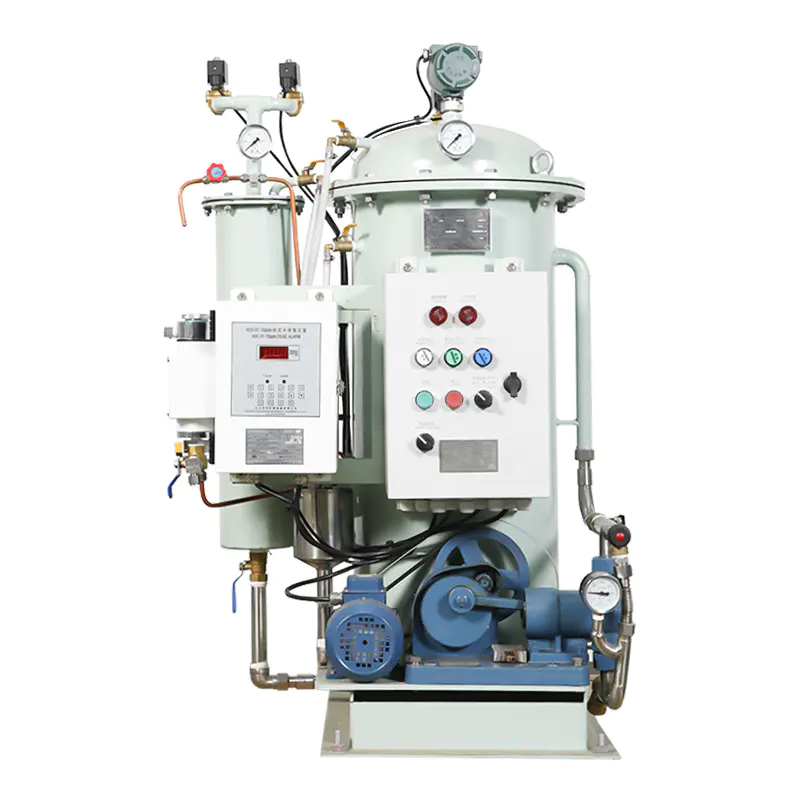

7. Salinometer (Assembled in the Control Box)

The salinometer continuously monitors the salinity of the produced freshwater. The salinity alarm point is adjustable.

8. Control Box

The control box is provided by the manufacturer and includes: motor switch, operation indicator light, salinometer, remote alarm, and equipment start-up.

Uses

The hot water tank is an important equipment for heating water in marine engineering, mainly used in ship heating systems. Common types include electric heating marine hot water tanks and seawater/freshwater heating hot water tanks, which are characterized by stable operation and complete specifications. Manufacturers usually provide a variety of sizes of customized services.

Hot water tanks are divided into electric heating marine hot water tanks and seawater/freshwater heating hot water tanks according to the heating method. Electric heating type uses electric energy and is suitable for different ship environments; seawater/freshwater heating type uses the existing heat source of the ship to heat water. Both types are characterized by stable operation and complete specifications, and support various sizes of customized needs.

Related Products

15ppm Bilge Water Separation HBN-0.1

HPN Series 15ppm bilge separator, all kinds of ruels used by ships, including the residual oil with extremely high density and emulsified oil mixture, can be separated effectively,and the effluent oil content is no more than 5ppm.

15ppm Bilge Water Separator HBN-0.25

The HBN series 15ppm bilge water separator is a high-tech product in the field of marine environmental protection, designed and developed in accordance with the International Maritime Organization IMO.MEPC 107(49) resolution, 'Revised Guidelines and Technical Requirements for Bilge Water Pollution Prevention Equipment in Ship Engine Rooms'.

15ppm Bilge Water Separator HBN-0.5

HPN Series 15ppm bilge separator, all kinds of ruels used by ships, including the residual oil with extremely high density and emulsified oil mixture, can be separated effectively,and the effluent oil content is no more than 5ppm.

Inquire Now

If you are interested in our products, please leave your email, and we will contact you as soon as possible, thank you!