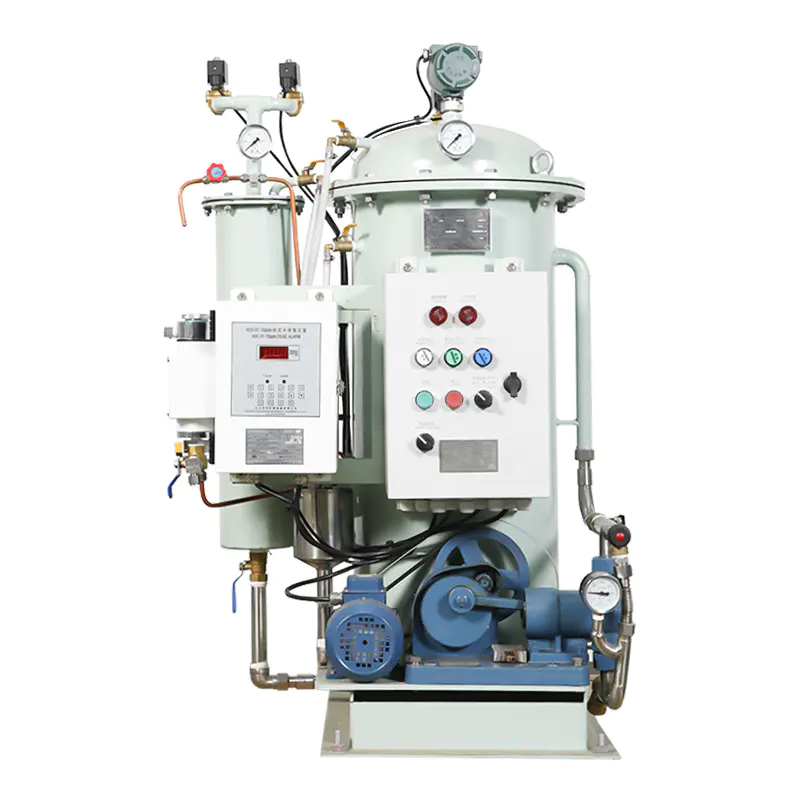

Sewage Treatment Device HBNA-20

Category:

HBNA Series Sewage Treatment Plant

Keywords:

Sewage Treatment Device HBNA-20

The HBNA series domestic sewage treatment device uses a combination of oxidation degradation, membrane microfiltration, and physical disinfection to treat sewage from ship toilets, kitchens, and bathrooms (also applicable to government agencies, schools, hotels, residential areas, and factories and mines).

Phone:

Email:

Product Details

The HBNA series domestic sewage treatment device uses a combination of oxidation degradation, membrane microfiltration, and physical disinfection and sterilization to treat domestic sewage from ships' toilets, kitchens, and bathrooms (also applicable to government agencies, schools, hotels, residential areas, and factories and mines).

Compared with similar products, it has the characteristics of small size, light weight, compact structure, no secondary pollution, and simple operation and maintenance.

Product Details

Water quality standards after treatment of the HBNA series domestic sewage treatment device

Heat-resistant coliform group: ≤100/100L

Total Suspended Solids (TSS): ≤35mg/L

5-day biochemical oxygen demand (BOD5): ≤25mg/L

Chemical Oxygen Demand (COD): ≤125mg/L

Acidity (PH value): 6-8.5

Residual chlorine: ≤0.5mg/L

The HBNA series domestic sewage treatment device uses a combination of oxidation degradation, membrane microfiltration, and physical disinfection and sterilization to treat domestic sewage from ships' toilets, kitchens, and bathrooms (also applicable to government agencies, schools, hotels, residential areas, and factories and mines).

Compared with similar products, it has the characteristics of small size, light weight, compact structure, no secondary pollution, and simple operation and maintenance.

The effluent treated by this device meets the emission standards of the International Maritime Organization (IMO) revised International Convention for the Prevention of Pollution from Ships (MARPOL 73/78), complies with (GB3552-2018 "Emission Standards for Ship Water Pollutants" Articles 5.2.2 and 5.2.4 and IMO.MEPC.227(64) "2012 Guidelines for the Implementation of Standards and Performance Tests for Sewage Treatment Plant Discharges"), and has obtained type approval from CCS, ZY, and ZC.

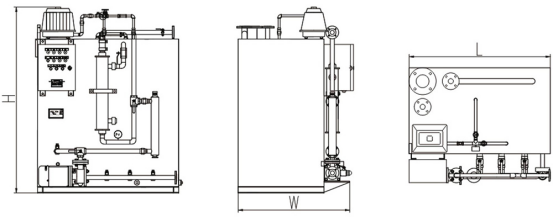

Model | Hydraulic Load (L/d) | Organic Load (kg/d BOD5) | Electrical System | Certificate | Total Power (kw) | Dimensions | Net Weight (kg) | ||

L(mm) | W(mm) | H(mm) | |||||||

HBNA-5 | 350 | 0.175 | AC220V/ AC380V/ AC440V | MEPC.227(64) And GB3552-2018 Article 5.2.2 and 5.2.4 | 2.0 | 590 | 620 | 1400 | ~380 |

HBNA-10 | 700 | 0.35 | 2.0 | 820 | 745 | 1400 | ~420 | ||

HBNA-15 | 1050 | 0.525 | 2.0 | 930 | 850 | 1450 | ~450 | ||

HBNA-20 | 1400 | 0.7 | 2.0 | 1100 | 915 | 1450 | ~480 | ||

HBNA-30 | 2100 | 1.05 | 2.5 | 1340 | 995 | 1470 | ~560 | ||

HBNA-40 | 2800 | 1.4 | 2.5 | 1510 | 1115 | 1470 | ~650 | ||

HBNA-50 | 3500 | 1.75 | 3.0 | 1590 | 1215 | 1570 | ~690 | ||

HBNA-60 | 4200 | 2.1 | 3.0 | 1740 | 1290 | 1570 | ~730 | ||

HBNA-70 | 4900 | 2.45 | 3.0 | 1750 | 1360 | 1770 | ~800 | ||

HBNA-80 | 5600 | 2.8 | 4.0 | 1900 | 1415 | 1770 | ~890 | ||

HBNA-90 | 6300 | 3.15 | 4.0 | 1900 | 1465 | 1920 | ~1010 | ||

HBNA-100 | 7000 | 3.5 | 4.0 | 2030 | 1515 | 1920 | ~1150 | ||

About MEPC.227(64)

On October 5, 2012, the International Maritime Organization (IMO) Marine Environment Protection Committee formally adopted Resolution IMO.MEPC.227(64), which made new requirements for the requirements of Annex IV of the MARPOL 73/78 International Convention for the Prevention of Pollution from Ships concerning ship sewage treatment plants. From January 1, 2016, all new and old ship sewage treatment plants must meet the requirements of this convention.

STANDARD/Convention | Suspended Solids | Biochemical Oxygen Demand | Chemical Oxygen Demand | Coliform Group | PH | Residual Chlorine |

Original Convention (before January 1, 2010) | <50mg/L(SS) | <50mg/L | NR | <250/100ml | 6-9 | As low as possible |

New Convention (from January 1, 2016) | <35mg/L(TSS) | <25mg/L | <125mg/L | <100/100mg | 6~8.5 | <0.5mg/L |

The hot water tank is an important equipment for heating water in marine engineering, mainly used in ship heating systems. Common types include electric heating marine hot water tanks and seawater/freshwater heating hot water tanks, which are characterized by stable operation and complete specifications. Manufacturers usually provide a variety of sizes of customized services.

Hot water tanks are divided into electric heating marine hot water tanks and seawater/freshwater heating hot water tanks according to the heating method. Electric heating type uses electric energy and is suitable for different ship environments; seawater/freshwater heating type uses the existing heat source of the ship to heat water. Both types are characterized by stable operation and complete specifications, and support various sizes of customized needs.

Previous page

Previous page

Related Products

15ppm Bilge Water Separation HBN-0.1

HPN Series 15ppm bilge separator, all kinds of ruels used by ships, including the residual oil with extremely high density and emulsified oil mixture, can be separated effectively,and the effluent oil content is no more than 5ppm.

15ppm Bilge Water Separator HBN-0.25

The HBN series 15ppm bilge water separator is a high-tech product in the field of marine environmental protection, designed and developed in accordance with the International Maritime Organization IMO.MEPC 107(49) resolution, 'Revised Guidelines and Technical Requirements for Bilge Water Pollution Prevention Equipment in Ship Engine Rooms'.

15ppm Bilge Water Separator HBN-0.5

HPN Series 15ppm bilge separator, all kinds of ruels used by ships, including the residual oil with extremely high density and emulsified oil mixture, can be separated effectively,and the effluent oil content is no more than 5ppm.

Inquire Now

If you are interested in our products, please leave your email, and we will contact you as soon as possible, thank you!